On Track Railroad Laser Additive Repair Manganese Steel

Leave a CommentRailroads rely heavily on the efficiency and reliability of their rail network infrastructure. In the USA, railroads spend billions of dollars on rail networks for replacement, improvement, and expansion. Trackwork frogs and crossing points are a particularly special component that requires constant and special attention. These are major track components for passing lines, turnouts, switching, […]

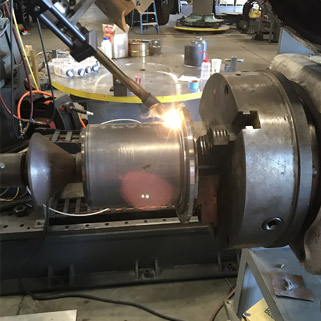

Laser Additive Remanufacturing

Leave a CommentClick to Expand Laser additive remanufacturing, also called laser cladding, is a cutting-edge technology that uses a laser to deposit material onto a component. It restores the component to its original condition or even with proper selection of metal to be laser clad, it can improve it. The process entails adding the metal layer by […]

Laser Cladding Cast Iron

Leave a CommentClick to Expand Cast iron is widely used in various industries due to its unique properties. However, the challenges of repairing these components can be daunting because of the welding process. Titanova, a leader in laser cladding, has developed a proprietary technique that enables the repair of the biggest castings. This article will explore the […]

Laser Cladding and Hard Facing for the Oil and Gas Industry

Leave a CommentClick to Expand Laser cladding and hard laser facing are welding techniques that provide a protective surface coating on metal parts. Also called laser metal deposition (LMD), laser cladding utilizes a focused laser beam to generate heat, and clad material is simultaneously fed into the resulting melt pool on the targeted surface area of a […]

What Is Weld Overlay?

Leave a CommentClick to Expand While welding is often used to join metals together, it can also be used as a protective technique. Weld overlay, also known as weld cladding, is the process of melting a protective layer of metal atop another metal surface. The application of laser light heats and melts the cladding metal onto the […]

Welding vs. Brazing vs. Soldering

Leave a CommentWelding, brazing, and soldering are three different processes that join metals. They all use heat to join metal primary differences between welding, brazing, and soldering are the melt temperatures of the metals or materials used in the process and what is being melted. There are many different welding techniques but here we will discuss only […]

Thermal Spray vs. Laser cladding

Comments Off on Thermal Spray vs. Laser claddingThis blog is meant to explain the differences between the thermal spray and laser cladding processes and help you understand the physical differences between each process. What is Thermal Spray? Thermal spraying refers to a group of coating processes in which finely divided metallic or nonmetallic materials [ceramics] are deposited in a molten or semi-molten […]

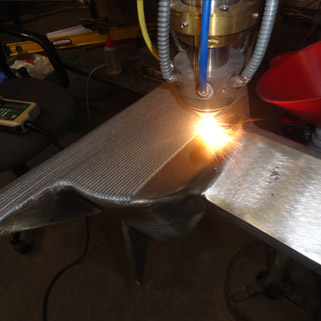

Introduction to the Laser Cladding Process

Comments Off on Introduction to the Laser Cladding ProcessLaser cladding—also referred to as laser metal deposition or Laser weld overlay—is a manufacturing technique used to add metal material to the surface of a component. It is generally used to create a protective coating that increases the functionality of the part or product. However, it can also be used to repair worn or damaged […]

Tags: laser cladding

Hardfacing Methods

Comments Off on Hardfacing MethodsHardfacing delivers a wear-resistant and hard coating of material on the surface of a worn component or a new component that will be subject to wear. There are various methods that can be used to apply the hardfacing layer. Common methods include: Arc Welding Oxygen-Acetylene Thermal Spraying Diode Laser Hardfacing The different hardfacing techniques provide […]

An Introduction to Laser Welding for Dissimilar Metals

Comments Off on An Introduction to Laser Welding for Dissimilar MetalsMany industries and applications require dissimilar materials to be joined for chemical, structural, and economic reasons. Combining dissimilar metals in a Weldment or for a weld overlay allow the use of the best properties of each metal. All industries benefit for this and is a primary importance when the overlay [cladding] is used in […]

Tags: dissimilar metals, laser welding