Industries We Served

Agriculture

Agriculture

Heat treating and hardfacing are typically used to produce thin, wear-resistant coatings to protect equipment when they come in touch with the ground or dust. Laser hardfacing from Titanova can help with the life enhancement of different components used across the agricultural industry.

Request a QuoteChemical Processing

Chemical Processing

At Titanova, specialized corrosion-resistant materials for valve gates and plugs, pump components, shafts, and piping are laser clad with low chemical dilution, making laser cladding ideal for various chemical processing applications, like acidic and caustic chemicals.

Request a QuoteMining

Mining

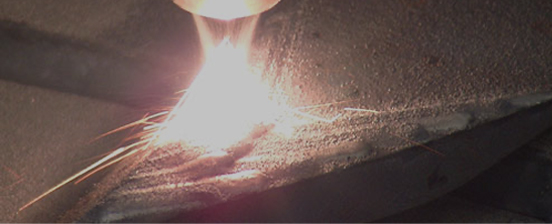

Mining equipment operates in some of the harshest environments, requiring high durability and protection from constant wear. Titanova’s laser hardfacing applies carbide overlays on components like excavator buckets, drill bits, and shovels, allowing them to resist the intense abrasion caused by rocks and other hard materials.

Request a QuoteMarine

Marine

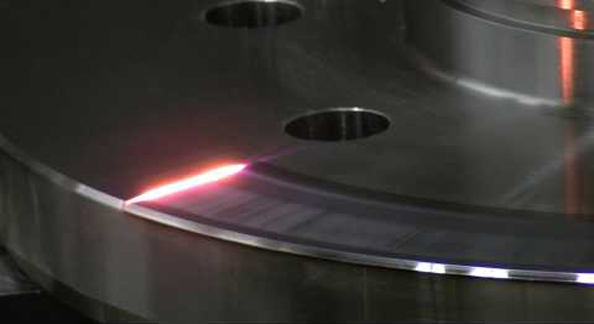

Laser cladding can repair engine crankshafts, screw shafts, and turbines to generate a smooth finish and low heat-affected zones. In addition, Titanova laser clad aluminum and silicon bronze onto steel.

Request a QuoteEnergy and Recovery

Energy and Recovery

Titanova is a certified wind turbine main shaft remanufacturing shop using our laser cladding techniques. We have a handling capacity of up to 35,000 lbs. and can fix common wind turbine main shaft damage by cladding stainless steel on the surface of critical journal surfaces. In addition, Titanova has developed a unique technique for remanufacturing cast ductile and cast-iron wind turbine components.

Request a QuoteHeavy Equipment

Heavy Equipment

Titanova Laser provides advanced laser cladding technology for the Heavy Equipment industry, helping extend the lifespan of machinery and enhance its performance. This technology is particularly useful for repairing and restoring worn-out parts, reducing downtime, and increasing productivity.

Request a QuoteTransportation

Transportation

Titanova’s laser cladding technique is ideal for special railroad trackwork, including frogs and crossing diamonds fabricated from cast austenitic high manganese steel (Hadfield steel). This type of steel is utilized in transportation because of its high toughness and exceptional work-hardening characteristics.

Request a QuoteAutomotive

Automotive

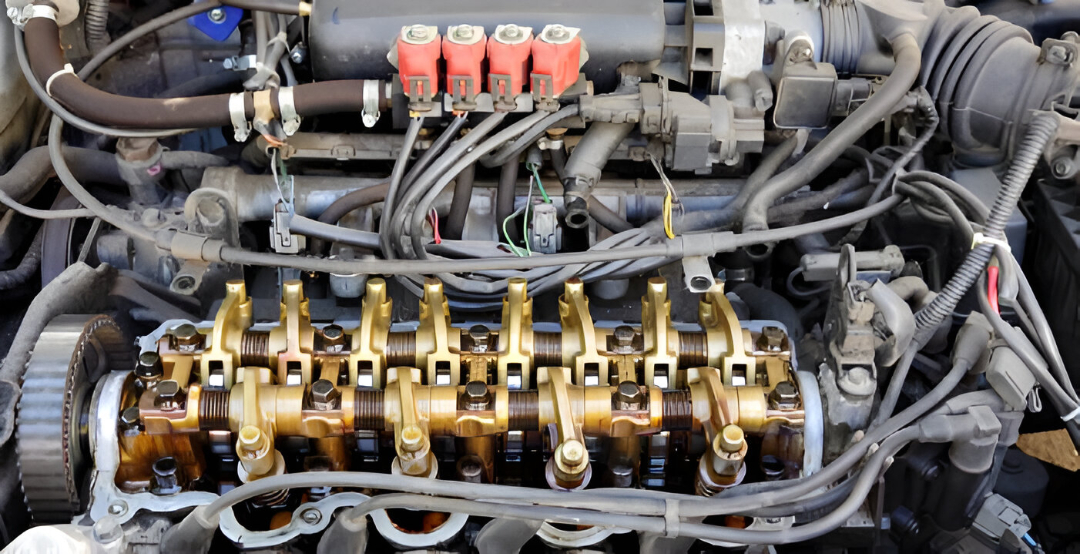

Titanova enhances automotive components with laser cladding and low-heat welding to create durable, wear-resistant surfaces on parts like camshafts and valves—without causing distortion. Laser heat treating and tempering improve hardness and fatigue resistance in gears, sprockets, and brakes, helping vehicles perform reliably with less wear over time.

Request a Quote