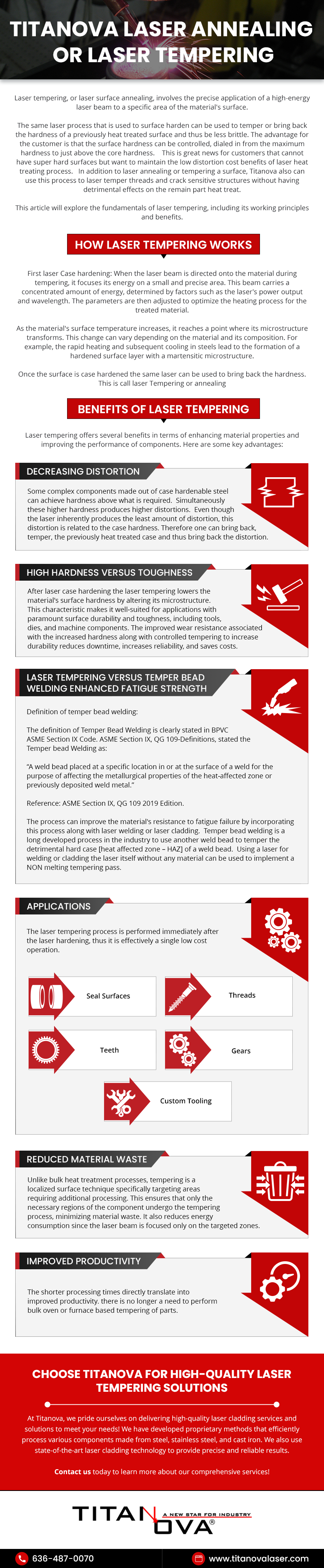

Titanova Laser Annealing or Laser Tempering

Leave a CommentLaser tempering, or laser surface annealing, involves the precise application of a high-energy laser beam to a specific area of the material’s surface.

The same laser process that is used to surface harden can be used to temper or bring back the hardness of a previously heat treated surface and thus be less brittle. The advantage for the customer is that the surface hardness can be controlled, dialed in from the maximum hardness to just above the core hardness. This is great news for customers that cannot have super hard surfaces but want to maintain the low distortion cost benefits of laser heat treating process. In addition to laser annealing or tempering a surface, Titanova also can use this process to laser temper threads and crack sensitive structures without having detrimental effects on the remain part heat treat.

This article will explore the fundamentals of laser tempering, including its working principles and benefits.

How Laser Tempering Works

First laser Case hardening: When the laser beam is directed onto the material during tempering, it focuses its energy on a small and precise area. This beam carries a concentrated amount of energy, determined by factors such as the laser’s power output and wavelength. The parameters are then adjusted to optimize the heating process for the treated material.

As the material’s surface temperature increases, it reaches a point where its microstructure transforms. This change can vary depending on the material and its composition. For example, the rapid heating and subsequent cooling in steels lead to the formation of a hardened surface layer with a martensitic microstructure.

Once the surface is case hardened the same laser can be used to bring back the hardness. This is call laser Tempering or annealing

Benefits of Laser Tempering

Laser tempering offers several benefits in terms of enhancing material properties and improving the performance of components. Here are some key advantages:

Decreasing Distortion

Some complex components made out of case hardenable steel can achieve hardness above what is required. Simultaneously these higher hardness produces higher distortions. Even though the laser inherently produces the least amount of distortion, this distortion is related to the case hardness. Therefore one can bring back, temper, the previously heat treated case and thus bring back the distortion.

High Hardness versus Toughness

After laser case hardening the laser tempering lowers the material’s surface hardness by altering its microstructure. This characteristic makes it well-suited for applications with paramount surface durability and toughness, including tools, dies, and machine components. The improved wear resistance associated with the increased hardness along with controlled tempering to increase durability reduces downtime, increases reliability, and saves costs.

Laser Tempering Versus Temper bead welding Enhanced Fatigue Strength.

Definition of temper bead welding:

The definition of Temper Bead Welding is clearly stated in BPVC ASME Section IX Code. ASME Section IX, QG 109-Definitions, stated the Temper bead Welding as:

“A weld bead placed at a specific location in or at the surface of a weld for the purpose of affecting the metallurgical properties of the heat‐affected zone or previously deposited weld metal.”

Reference: ASME Section IX, QG 109 2019 Edition.

The process can improve the material’s resistance to fatigue failure by incorporating this process along with laser welding or laser cladding. Temper bead welding is a long developed process in the industry to use another weld bead to temper the detrimental hard case [heat affected zone – HAZ] of a weld bead. Using a laser for welding or cladding the laser itself without any material can be used to implement a NON melting tempering pass.

Applications

The laser tempering process is performed immediately after the laser hardening, thus it is effectively a single low cost operation..

Applications:

- Seal surfaces

- Threads

- Teeth

- Gears

- Custom Tooling

Reduced Material Waste

Unlike bulk heat treatment processes, tempering is a localized surface technique specifically targeting areas requiring additional processing. This ensures that only the necessary regions of the component undergo the tempering process, minimizing material waste. It also reduces energy consumption since the laser beam is focused only on the targeted zones.

Improved Productivity

The shorter processing times directly translate into improved productivity. there is no longer a need to perform bulk oven or furnace based tempering of parts

Choose Titanova for High-Quality Laser Tempering Solutions

At Titanova, we pride ourselves on delivering high-quality laser cladding services and solutions to meet your needs! We have developed proprietary methods that efficiently process various components made from steel, stainless steel, and cast iron. We also use state-of-the-art laser cladding technology to provide precise and reliable results.

Contact us today to learn more about our comprehensive services!