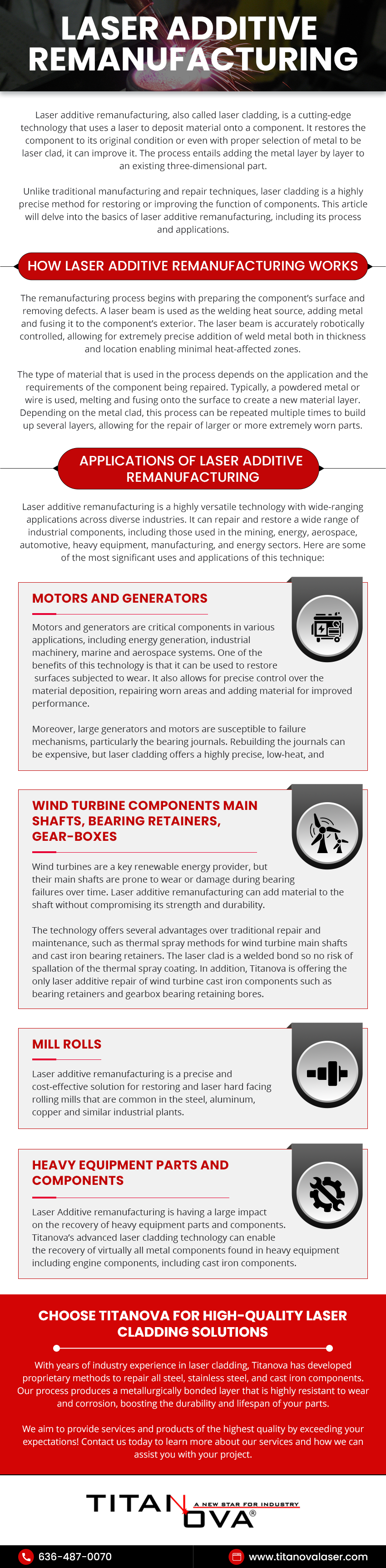

Laser additive remanufacturing, also called laser cladding, is a cutting-edge technology that uses a laser to deposit material onto a component. It restores the component to its original condition or even with proper selection of metal to be laser clad, it can improve it. The process entails adding the metal layer by layer to an existing three-dimensional part.

Unlike traditional manufacturing and repair techniques, laser cladding is a highly precise method for restoring or improving the function of components. This article will delve into the basics of laser additive remanufacturing, including its process and applications.

How Laser Additive Remanufacturing Works

The remanufacturing process begins with preparing the component’s surface and removing defects. A laser beam is used as the welding heat source, adding metal and fusing it to the component’s exterior. The laser beam is accurately robotically controlled, allowing for extremely precise addition of weld metal both in thickness and location enabling minimal heat-affected zones.

The type of material that is used in the process depends on the application and the requirements of the component being repaired. Typically, a powdered metal or wire is used, melting and fusing onto the surface to create a new material layer. Depending on the metal clad, this process can be repeated multiple times to build up several layers, allowing for the repair of larger or more extremely worn parts.

Applications of Laser Additive Remanufacturing

Laser additive remanufacturing is a highly versatile technology with wide-ranging applications across diverse industries. It can repair and restore a wide range of industrial components, including those used in the mining, energy, aerospace, automotive, heavy equipment, manufacturing, and energy sectors. Here are some of the most significant uses and applications of this technique:

Motors and Generators

Motors and generators are critical components in various applications, including energy generation, industrial machinery, marine and aerospace systems. One of the benefits of this technology is that it can be used to restore surfaces subjected to wear. It also allows for precise control over the material deposition, repairing worn areas and adding material for improved performance.

Moreover, large generators and motors are susceptible to failure mechanisms, particularly the bearing journals. Rebuilding the journals can be expensive, but laser cladding offers a highly precise, low-heat, and cost-effective solution to this problem.

Wind Turbine Components Main Shafts, Bearing Retainers, Gear-boxes

Wind turbines are a key renewable energy provider, but their main shafts are prone to wear or damage during bearing failures over time. Laser additive remanufacturing can add material to the shaft without compromising its strength and durability.

The technology offers several advantages over traditional repair and maintenance, such as thermal spray methods for wind turbine main shafts and cast iron bearing retainers. The laser clad is a welded bond so no risk of spallation of the thermal spray coating. In addition, Titanova is offering the only laser additive repair of wind turbine cast iron components such as bearing retainers and gearbox bearing retaining bores.

Mill Rolls

Laser additive remanufacturing is a precise and cost-effective solution for restoring and laser hard facing rolling mills that are common in the steel, aluminum, copper and similar industrial plants.

Heavy Equipment Parts and Components

Laser Additive remanufacturing is having a large impact on the recovery of heavy equipment parts and components. Titanova’s advanced laser cladding technology can enable the recovery of virtually all metal components found in heavy equipment including engine components, including cast iron components.

Choose Titanova for High-Quality Laser Cladding Solutions

With years of industry experience in laser cladding, Titanova has developed proprietary methods to repair all steel, stainless steel, and cast iron components. Our process produces a metallurgically bonded layer that is highly resistant to wear and corrosion, boosting the durability and lifespan of your parts.

We aim to provide services and products of the highest quality by exceeding your expectations! Contact us today to learn more about our services and how we can assist you with your project.