Guide to Laser Welding

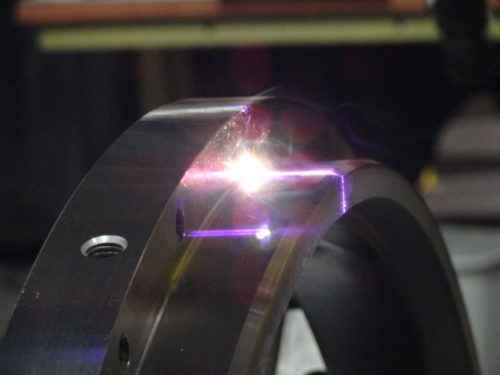

Comments Off on Guide to Laser WeldingWhat Is Laser Welding? To understand laser welding we must step back and generally describe what welding is. Welding is joining similar materials of different shapes and similar melt temperatures. These materials are typically the same material. The welding process concentrates heat at the interface to melt the edges and upon solidification creates a structurally […]

Tags: laser welding

What Metals Can You Braze?

Comments Off on What Metals Can You Braze?Brazing is used to join metal parts and can be applied to a wide array of materials, like brass, copper, stainless steel, aluminum, zinc-coated steel, and ceramics. Laser brazing offers some distinct advantages in applications that require the joining of non-similar metals. Contact Us Laser Brazing Services What Is Brazing? Brazing is a process by […]

Tags: braze

What’s the Difference Between Hardfacing and Cladding?

Comments Off on What’s the Difference Between Hardfacing and Cladding?“Hardfacing” and “cladding” are two terms that are often used synonymously, not realizing they are distinctly different applications. If so, you are in good company, as it is a common misconception. Hardfacing is a welding process that applies a high-wear surface to add protection and extend the life of the object. The material welded […]

Tags: cladding, hardfacing, laser cladding, laser hardfacing

What Is Laser Hardening?

1 CommentLaser hardening—also referred to as laser case hardening—is a heat treating process used to improve the strength and durability of component surfaces. It employs the use of high-powered diode lasers that apply energy to heat localized areas of the component surface. As the lasers move across the surface it instantaneously heats the surface and […]

Tags: hardening, laser hardening

Traditional Welding vs. Laser Welding

Comments Off on Traditional Welding vs. Laser WeldingWelding is a fabrication process that employs heat to join two or more separate pieces. Currently, industry professionals utilize both traditional arc-based welding, spot welding, and laser welding methods for their operations. Both process variations offer unique characteristics that make them suitable for different cases. For example, traditional welding accommodates less precise workpiece fit-up, while […]

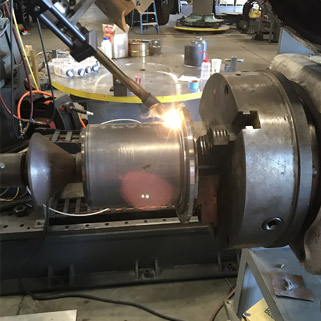

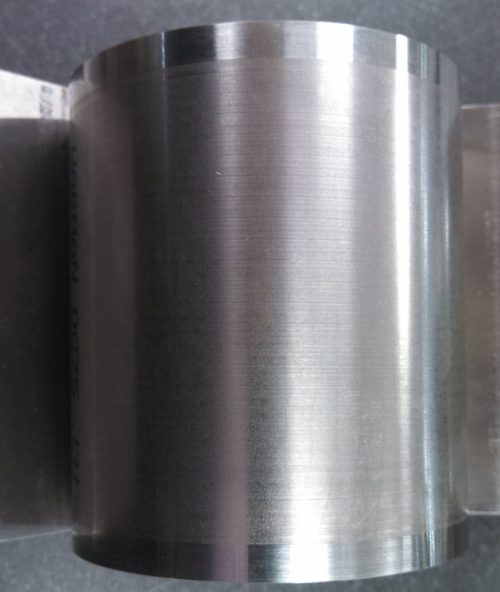

Laser Cladding for Remanufacturing

Comments Off on Laser Cladding for RemanufacturingTitanova’s laser cladding is a new weld repair process that can be used to restore critically worn surfaces of metal parts. Typical critical surfaces include the bearing journals, seal surfaces, hydraulic shafts, valve seats/gates, etc. Titanova’s laser cladding remanufacturing technology creates less heat, dilution, and much smoother weld overlays. This is compared to traditional arc […]

Tags: cladding, refurbishing, remanufacture

Tungsten Carbide Laser Hard Facing

Comments Off on Tungsten Carbide Laser Hard FacingTitanova is a premier supplier of Tungsten Carbide [WC] laser hard facing NOW 70% by weight Titanova is continuing to pursue new hard facing materials and laser hard facing processes to address critical wear problems for our customers. The wear issues specifically addressed here are abrasion and erosive wear from uniform distributed solid particles suspended […]

Laser Clad Overlays of Cobalt 6 – Stellite®

Comments Off on Laser Clad Overlays of Cobalt 6 – Stellite®Titanova is a premier supplier of laser clad overlays of Cobalt 6 – Stellite® and other equivalent cobalt alloy. Titanova has developed a variety of laser cladding techniques to laser clad defect free Cobalt 6 – Stellite® alloys on journals, valve seats, ball seats, etc. These laser cladding processes include both power and hot cored […]

Tags: cobalt 6, laser cladding, stellite

Titled Puddle Forming and Shaping with Primary and Secondary Lasers.

Comments Off on Titled Puddle Forming and Shaping with Primary and Secondary Lasers.Titanova was just awarded the patent, Titled Puddle Forming and Shaping with Primary and Secondary Lasers. This Patent is available for licensing. Description or Summary of Invention So for one skilled in the art of welding one can appreciate the advantage of being able to shape the puddle such that the bead of the final […]

Titanova Offers Benefits of Both Hot And Cold Wire Feed Laser Welding

Comments Off on Titanova Offers Benefits of Both Hot And Cold Wire Feed Laser WeldingHot And Cold Wire Feed Laser Welding Titanova in its continuing effort to develop new laser process technologies for the benefit of the industry is offering both hot and cold wire enhanced laser welding. This unique laser process application offers improve weld root reinforcement over laser autogenous welding. The wire feed laser welding process is […]